- Empty cart.

- Continue Shopping

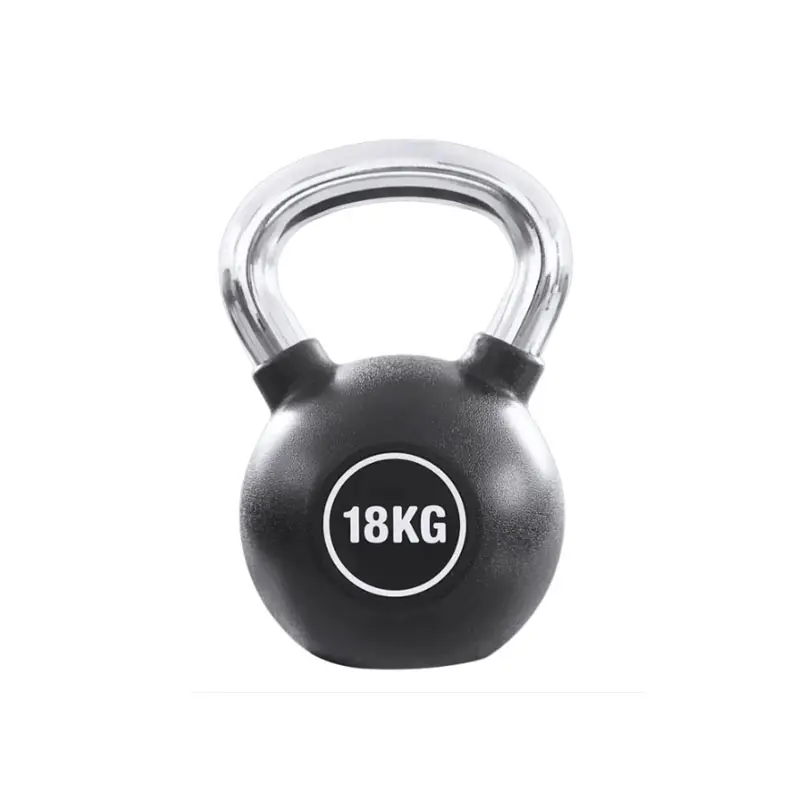

PU Kettlebell

- Classic electroplated handle, comfortable and smooth to hold, rust-proof and more durable.

- Solid cast iron for reliable, long-lasting strength

- PU coating, fine machining, no rough edges.

Features

PU kettlebells and steel competition kettlebells comparison between the two:

Steel Competition Kettlebells

Material: High-quality steel

Advantages:

Durability: Steel kettlebells are extremely durable and can withstand heavy use, including drops, without deforming or getting damaged.

Disadvantages:

Noise and Impact: When dropped, steel kettlebells can be noisy and may cause more damage to flooring.

Cold Grip: Steel can feel cold to the touch, especially in colder environments.

PU Competition Kettlebells

Material: Steel core covered with a layer of polyurethane

Advantages:

Durability: Polyurethane is highly resistant to wear and tear, more so than traditional rubber or vinyl. It can withstand heavy use and resist chipping and cracking.

Floor Protection: The polyurethane coating helps protect floors and reduces noise when the kettlebell is placed down or dropped.

Disadvantages:

Cost: PU kettlebells are usually more expensive than standard steel kettlebells due to the additional material and manufacturing process.

Size: The polyurethane coating can add slight bulk compared to bare steel kettlebells, potentially affecting the handling slightly.

Summary

Steel Competition Kettlebells are the traditional choice, offering extreme durability, consistency in size and shape, and a reliable grip. They are widely accepted in competitions and training facilities.

PU Competition Kettlebells offer additional benefits such as better floor protection, reduced noise, and a more comfortable grip. However, they tend to be more expensive and slightly bulkier than their steel counterparts.

Recommendation

For Competitive Athletes: If you are training for competitions, traditional steel competition kettlebells are often the best choice due to their widespread use and standardization.

For Home Use or General Fitness: PU competition kettlebells might be more suitable if you are concerned about protecting your floors, reducing noise, and having a more comfortable grip.

Reviews

There are no reviews yet.