- Empty cart.

- Continue Shopping

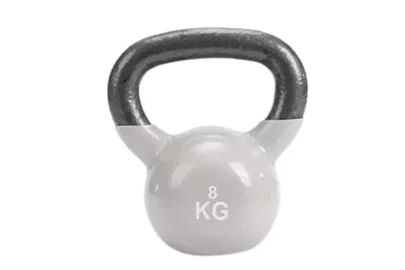

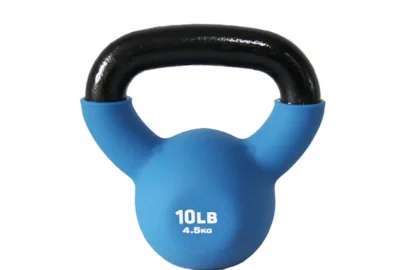

Neoprene Dipping Kettlebell

1. Durable cast iron is wrapped with color-coded vinyl to prevent corrosion, increase durability and protect floors.

2. Flat base allows upright storage.

3. Used for swings, deadlifts, and squats.

What Are Neoprene Dipped Kettlebells?

Neoprene-dipped kettlebells are made by coating a solid iron or steel kettlebell with a layer of neoprene, a synthetic rubber material. This process enhances the kettlebell’s functionality and appearance, providing several benefits over traditional uncoated kettlebells.

The Craftsmanship Process

1. Material Selection

Core Material: High-quality iron or steel is chosen for the core of the kettlebell to ensure strength and durability.

Neoprene Quality: Premium neoprene is selected for its flexibility, durability, and protective properties.

2. Manufacturing Process

Casting the Core: The iron or steel core is cast into the desired kettlebell shape using precise molds to ensure consistency in weight and balance.

Smoothing the Surface: The core is polished to remove any imperfections that could affect the adherence of the neoprene coating.

3. Neoprene Dipping

Coating Application: The kettlebell is dipped into a vat of liquid neoprene, ensuring an even, thick coating that fully encapsulates the core.

Curing: The coated kettlebell is then cured in a controlled environment to solidify the neoprene and ensure a tight, durable bond with the core.

4. Quality Control

Inspection: Each kettlebell undergoes rigorous inspection to check for any defects in the coating, weight accuracy, and balance.

Testing: Sample kettlebells are subjected to stress tests to ensure they meet durability and performance standards.

Reviews

There are no reviews yet.