- Empty cart.

- Continue Shopping

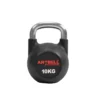

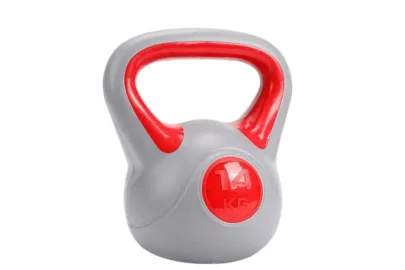

Competition Kettlebells

- Chromed anti-rust handle,easy to grip,comfortable to hold.

- Handle and sphere,one piece molding,anti-break.

- Easily identified by color and clear weight identification mark..

Features

Competition kettlebells are typically made from a few specific materials that ensure their durability, consistency, and performance. Here are the primary materials used in the construction of competition kettlebells:

1. Steel

- Primary Material: Most competition kettlebells are made from high-quality steel.

- Durability: Steel is extremely durable, ensuring that the kettlebell can withstand heavy use and drops without deforming.

- Consistency: The use of steel allows for uniform size and shape across different weights, which is crucial for maintaining consistent technique and handling.

2. Handle Coating

- Bare Steel or Powder Coated: Handles of competition kettlebells can either be left as bare steel or coated with a powder to improve grip and reduce rusting.

- Rust-Resistant: High-quality competition kettlebells often have handles that are treated to be rust-resistant, ensuring longevity and maintaining a smooth grip over time.

3. Color Coding

- Paint: Different weights of competition kettlebells are typically color-coded using durable paint. This paint is designed to be chip-resistant and long-lasting.

- Standardization: The color coding is standardized (e.g., 8 kg is pink, 12 kg is blue, 16 kg is yellow, etc.), making it easy to identify the weight quickly.

4. Finish

- Smooth Finish: The body of the kettlebell often has a smooth finish to reduce chafing and ensure a comfortable grip, especially important during high-repetition exercises.

- Polished or Matte: The finish can be polished for a smoother surface or matte to provide a slightly better grip.

Reviews

There are no reviews yet.